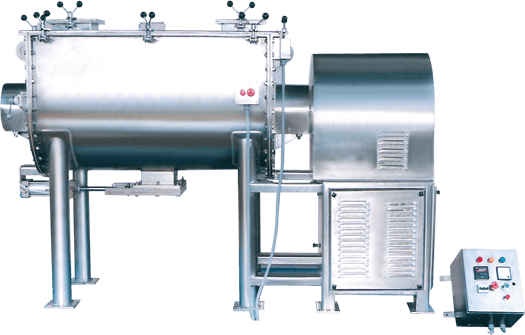

Dough Mixer Or Mass Mixer Manufacturer

We have been manufacturing Mass Mixer for several industries also known as Dough Mixer. Mass mixer ideally used for mixing both wet & dry materials to provide uniform mixing. Designed with utmost precision & perfection our offered mass mixers are used for mixing & blending purposes. The mass mixer is suitable for mixing of wet mass, dry powder, dry powder with wet mass, etc, for the preparation of pharmaceutical mass for preparing tablets and similar other applications. The mass mixer gives through mixing due to its unique blade design and the angle of the blade. Powder & Mass Mixer machines are designed for efficient and homogeneous mixing of dry and wet powders.

Benefits of using Gaurav Engineering Mass Mixer

1. Models are available with working volume 50,100 & 200 kgs. At bulk density of 0.50gms/cc.

2. All contact parts Stainless Steel 316 or 316L & Non Contact Parts AISI 304.

3. Compact design & Easy to clean and operate.

4. Single stirrer for dry & wet mixing.

5. Safety guards are provided for all moving parts.

6. Interlocking system with top dust cover, to avoid accident, during process.

7. Thrust bearings are provided to carry out rigid thrust load.

8. All contact parts in S.S. Constructions. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish.

9. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers.

Working Principle of Dough Mixer or Mass Mixer

Shell: Consisting of ‘U’ trough of suitable dimensions. Construction of S.S. and side plates duly M.S. stiffened from outside and from inside with S.S.

Mixing Mechanism: Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage.

Charging: From the top charging can be done through a hinge able lid, hopper or Nozzle can be provided for additional spraying of additives.

Discharge: By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge.

Drive: Consisting of suitable H.P. TEFC 3 Phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable Plummer block.

Mounting: Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings.

| Model - Mass Mixer | MM-50 | MM-100 | MM-150 | MM-200 | MM-300 |

|---|---|---|---|---|---|

| Working Capacity | 110 Ltr. | 220 Ltr. | 330 Ltr. | 440 Ltr. | 560 Ltr. |

| Electrical Motor | 3HP / 2.2KW / 144RPM / 415V / 50HZ / 3Phase | 5HP / 3.7KW / 144 RPM / 415V / 50HZ / 3Phase | 7.5HP / 5.5KW / 144RPM /415V / 50HZ / 3Phase | 10HP / 5.5KW / 144RPM / 415V / 50HZ / 3Phase | 15HP / 7.4KW / 144RPM / 415V / 50HZ / 3Phase |

| Over all dimensions in mm | L x B x H 1700 x 740 x 940 | L x B x H 2300 x 7400 x 940 | L x B x H 2135 x 790 x 1300 | L x B H 2475 x 100 x 1500 | L x B x H2650 x 1050 x 1600 |

| Case dimension in mm | 1900 x 950 x 1150 | 1900 x 950 x 1150 | 2350 x 1000 x 1500 | 2475 x 1000 x 1500 | 2650 x 1050 x 1600 |

| Net weight in kgs. | 350 | 450 | 550 | 600 | 700 |

| Gross weight in Kgs. | 450 | 600 | 750 | 800 | 1000 |

Industry We Serve

Chemical Industry Equipment Herbal Industry Equipment

Pesticides & Insecticides Industry Equipment

Food Processing Industry Equipment

Paint Manufacturing Industry Equipment

Phenol Formaldehyde Resin Industry Equipments

Starch Industry Equipments

Dyes Industry Equipments

Polymer Industry Equipments

Oil Plants Equipments

Phosphates Industry Equipments

Food and Edible Oil Industry Equipments

Detergents Industry Equipments