Ribbon Blender Manufacturer

The Ribbon Blender machine or Mixer operates raw materials mixing powder or granules of Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive products. Ribbon Blender is used many industries for mixing and drying powders such as food powder, carbon black, granules, pellets and various other solid forms , Customer many different industry customer with many application for ribbon type mixer and blender machines.

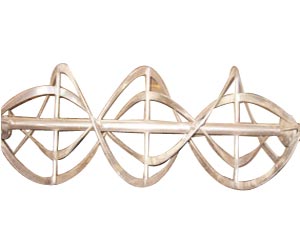

Working Principle of Ribbon Blender / Mixer

The Stainless Steel Blender is an best efficient and versatile product blending machine for mixing of dry granules & powders homogeneously. Approx two third of the product volume of the container of Ribbon Blender is filled to ensure proper mixing materials. Ribbon Blender gives best super result for mixing of product like dry powder & granules due to the design and shape of the materials mixing ribbon and product container.

Product Material should be charge from the top side. There are Open lid or port/ports should be provided on the top cover to charge the product material as well as for air vent. Our blender machine with One discharge valve provided at the bottom side at centre of the container. The blender machine discharge height could be adjust as per the customer requirement, so that product material gets discharge in the other container directly or fixed screw transfer or vacuum transfer systems optionally extra so that product material handling time for discharge is nil and the operation is dust free. The blender unit is consist of electrical motor, worm reduction gear, belt drive or heavy duty chain between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Product Container having four nos. of legs with discharge valve & top cover of machine, Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts for safety.

We have been a manufacturer of Ribbon blender for many prestigious companies & plants

We also provide suitable feeding machine for the ribbon blender, such as screw conveyor, vacuum conveyor,bucket elevator, flexible screw conveyor etc.

1. Capacity Available from 100 kg to 10,000 kgs

2. All contact parts Stainless Steel 316 or 316L & Non Contact Parts AISI 304.

3. Dust free operation.

4. Quick and Fast and uniform mixing & draying at low temperature.

5. Blender with Rapid & discharge / Zero hold-up after discharge

6. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers

| Model - Mass Mixer | MM-50 | MM-100 | MM-150 | MM-200 | MM-300 |

|---|---|---|---|---|---|

| Working Capacity | 110 Ltr. | 220 Ltr. | 330 Ltr. | 440 Ltr. | 560 Ltr. |

| Electrical Motor | 3HP / 2.2KW / 144RPM / 415V / 50HZ / 3Phase | 5HP / 3.7KW / 144 RPM / 415V / 50HZ / 3Phase | 7.5HP / 5.5KW / 144RPM /415V / 50HZ / 3Phase | 10HP / 5.5KW / 144RPM / 415V / 50HZ / 3Phase | 15HP / 7.4KW / 144RPM / 415V / 50HZ / 3Phase |

| Over all dimensions in mm | L x B x H 1700 x 740 x 940 | L x B x H 2300 x 7400 x 940 | L x B x H 2135 x 790 x 1300 | L x B H 2475 x 100 x 1500 | L x B x H2650 x 1050 x 1600 |

| Case dimension in mm | 1900 x 950 x 1150 | 1900 x 950 x 1150 | 2350 x 1000 x 1500 | 2475 x 1000 x 1500 | 2650 x 1050 x 1600 |

| Net weight in kgs. | 350 | 450 | 550 | 600 | 700 |

| Gross weight in Kgs. | 450 | 600 | 750 | 800 | 1000 |

Industry We Serve

Chemical Industry Equipment Herbal Industry Equipment

Pesticides & Insecticides Industry Equipment

Food Processing Industry Equipment

Paint Manufacturing Industry Equipment

Phenol Formaldehyde Resin Industry Equipments

Starch Industry Equipments

Dyes Industry Equipments

Polymer Industry Equipments

Oil Plants Equipments

Phosphates Industry Equipments

Food and Edible Oil Industry Equipments

Detergents Industry Equipments