Heat Exchanger / Condenser Manufacturer

We are manufacturer of Shell and Tube Heat Exchanger / Condenser in India. We have been manufacturer & supplier of Shell and Tube Heat Exchanger / Condenser to prestige Industries since many years.

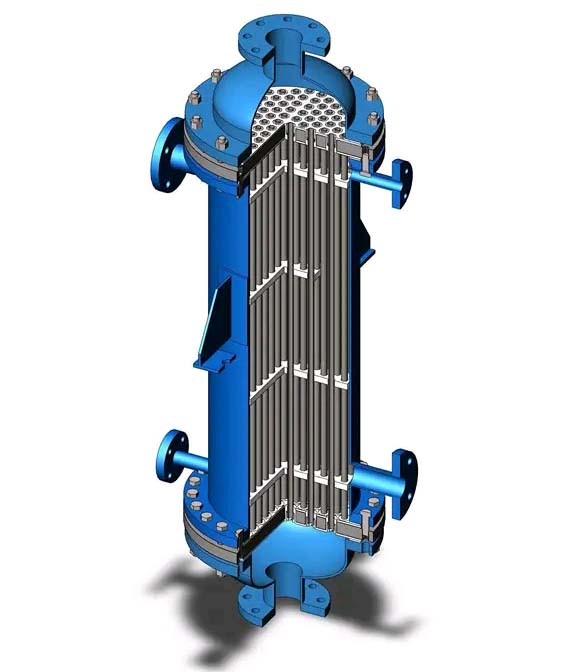

Heat Exchangers / Condenser are designed and manufactured to facilitate indirect heat transfer between the two fluids. The two fluids can be liquid and liquid or vapor and liquid. The shell-and-tube heat exchanger / Condenser has two main areas – Tube side and Shell side.

Process of Shell and Tube type of Heat Exchanger / Condenser:-

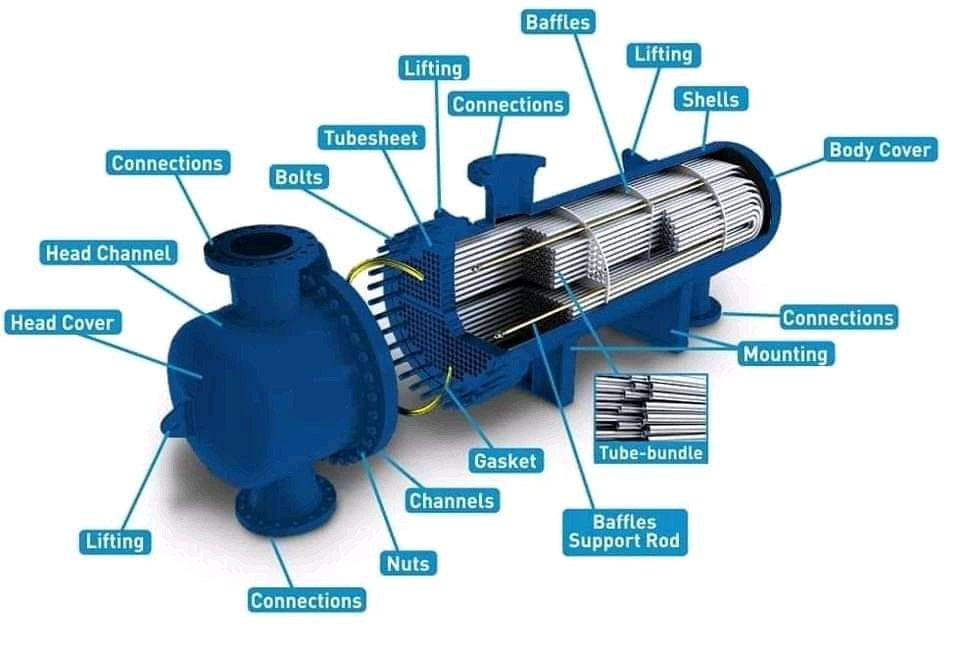

Main components of Shell and Tube type heat exchanger / Condenser are- Shell, Tube, Tube sheet, Baffles, Tie roads spacers and Channel.

• The Cylindrical Shell can be fabricated from rolled plate or from pipes.

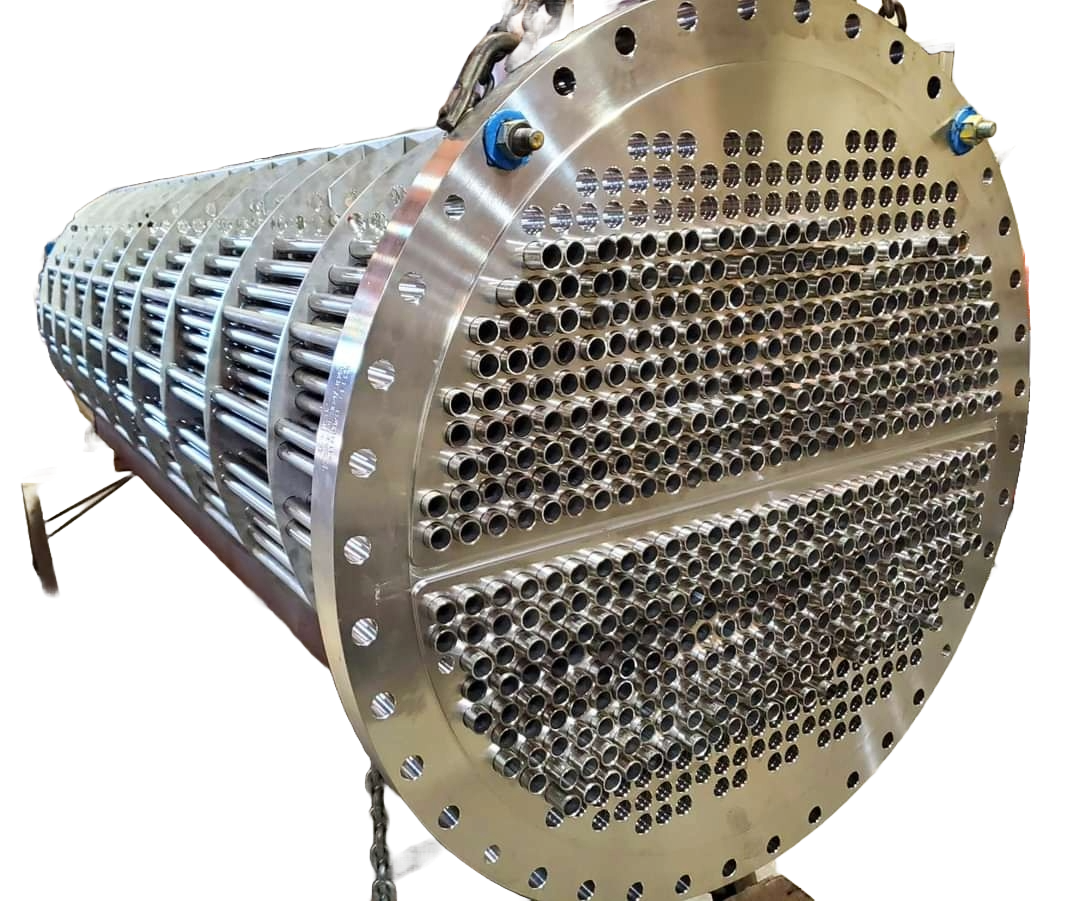

• Tubes can be plain tubes. Or heat transfer surface area of the tubes can be increased many folds by using finned tubes or corrugated tubes. Shell tube heat exchangers / Condenser with fin tubes are known as finned type heat exchanger and with corrugated tubes it is known as corrugated tube heat exchanger.

• Tubes of the heat exchanger / Condenser will be held on both the sides by Tube Sheets. Tubes will be inserted through holes provided on tube sheets. Tubes are firmly fitted in the tube sheet either by welding or by mechanical or hydraulic expansion.

• Baffles are provided to support the tubes, to maintain the space between the tubes and it also channelized the fluid flow as per design through the shell side of heat exchanger.

• Tie rods and Spacers will hold the baffle assembly together; and will also maintain the spacing between the baffles. One end of the tie rods are secured to the tube sheet and other ends are secure in the last baffle.

• Channels or Heads are provided for shell-and-tube heat exchangers / Condenser to contain the tube side fluid and to provide the desired flow path.

Shell and Tube Heat Exchangers / Condenser are used as Condensers, Reboilers, Process Heaters, Coolers and Falling Film Evaporator.

Benefits of using Gaurav Engineering Heat Exchanger / Condenser :-

• These heat exchangers / Condenser are supplied as per both customers’ specifications and drawing or custom-built based on process conditions. A well equipped design team understands the customers’ need and proposes the required design for their approval.

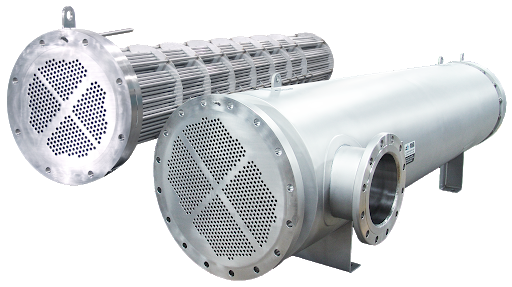

• Design as per TEMS, ASME Standard & Design of Condenser are very simple shape & scientifically.

• The heat transfer area ranges from 1 SQM. To 500 SQM.

• Design & Mfg with stainless steel Grade SS316L ,SS304L,IS 2062

• Easy maintenance and robust quality therefore more demand in the market.

• These Industrial Heat Exchanger / Condenser can be customized as per client’s requirements and Registered with leading consultants and third party inspection agency.

• Reliable After sales support and on time delivery.

• Pharmaceutical & Bulk Drugs, Chemical Industry, Herbal Industry, Pesticides & Insecticides Industry, Food Processing Industry, Paint Manufacturing Industry, Phenol Formaldehyde Resin Industry, Starch Industry, Dyes Industry, Polymer Industry, Oil Plants, Phosphates Industry, Food & Edible Oil Industry, Detergents Industry.

Industry We Serve

Chemical Industry Equipment Herbal Industry Equipment

Pesticides & Insecticides Industry Equipment

Food Processing Industry Equipment

Paint Manufacturing Industry Equipment

Phenol Formaldehyde Resin Industry Equipments

Starch Industry Equipments

Dyes Industry Equipments

Polymer Industry Equipments

Oil Plants Equipments

Phosphates Industry Equipments

Food and Edible Oil Industry Equipments

Detergents Industry Equipments